Thanks for the comments on my last post regarding more stitching on "Off the Grid." I'm still mulling it over, and have started making the mount while I decide. In the meantime, I proceeded with a printing test for my Take It Further Challenge piece.

I wanted to try printing on fabric that had been treated with fabric softener. I've not been totally happy with my results using Bubble Jet Set, and being able to use a simple household product appealed. I first ran across this idea in New Zealand Quilter magazine, then found more detailed instructions online, although I apologize to the writer - I did not notate her name. I only know that she is an Aussie and got the instructions from someone in her quilt group.

I cut a strip of muslin and soaked it in fabric softener, squeezed out the excess and hung it to dry as instructed. It's not supposed to make any difference what brand you use so I used the Downy I had on hand. The scent was so strong in this concentrated form that it was almost more than I could handle throughout the whole process.

The next day, I ironed it, having to mist slightly as was suggested to get the wrinkles under control. Then I cut a piece to size and ironed it to a piece of Jenkins Freezer paper. This stuff is great - so much heavier than the Reynolds freezer paper on the roll. I think fabric sticks to it better too. I had no problem feeding this through my Epson Stylus Photo RX500 printer. I was extremely impressed with the sharpness of the prints and the true and saturated nature of the color. As a control, I also printed on a piece of pima cotton that had been treated with Bubble Jet set back in 2004 and stored in a sealed freezer bag. I know; I was asking to skew the results. I've read that even old Bubble Jet Set that has been stored in its original bottle loses potency over time. But you know me: waste not, want not.

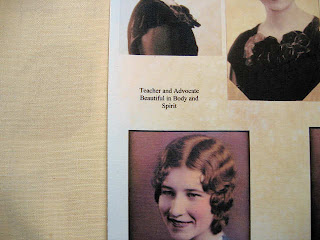

The Bubble Jet Set fabric is on the left. You can see how different the colors are - a more faded look, which has been my experience with printing on an ink jet printer.

Whereas the Bubble Jet Set treatment can be rinsed out in as little as 30 minutes, the fabric softener treatment needed to sit for 24 hours. Then it can be ironed and left to set for another 24 hours. My instructions didn't say how long to iron or which side of the fabric to iron on, so I opted to be safe and iron from the back (freezer paper still adhered). I placed it face down on a dishtowel and pressed with a hot iron for a minute or more. When I turned it over, I could see that some of the ink had transferred to the towel, which I did not think was a good sign. Brown spots like scorching also appeared and worried me. (It turned out that the fabric was not scorched, just the softener that had turned.)

Yesterday, the second 24 hours was up and it was time to rinse both samples. Both treatments recommend a rinse in cool water and mild detergent, so I used my Orvus Paste. The Bubble Jet Set sample showed little if any ink in the water and no color loss or running on the fabric. Wow, this had not been my experience in the past with this, so I was thrilled. I was not as thrilled with what happened with the fabric softener sample. I'd cut it in two sections, and the first ran and ran. Ok, maybe my detergent is reacting badly, so I took the second section and just rinsed it in cool water, with the exact same results. What a huge disappointment.

I laid all my rinsed samples face down on the dishtowel again, and pressed them dry. I find this insures that all the wrinkles disappear and the photo stays square. When I turned them over, there was even more ink transfer to the towel from the fabric softener treated fabric, but no transfer from the Bubble Jet Set one. Here they are along side their unwashed twins.

So I guess you Aussies will have to tell me what I did wrong. Did I not let the fabric softener soak in enough? Did a leave too much on the surface of the fabric so that the ink didn't have a chance to penetrate the threads? Is your fabric softener of a different chemical composition than that sold in the United States? Is the ink for my particular model of printer the culprit?

Although I'm unhappy that the fabric softener experiment was such a huge failure, I'm very happy to have had success with the Bubble Jet Set, and found a way to feed my fabric through the printer without major jamming.

2 comments:

I don't use the fabric softener method so can't help there - I only print photos for artwork so the washability isn't an issue.

I used to have a business making photo memory quilts. I found that if you snip the leading corners (on the end that goes into the printer first) I rarely had any issues with the feeding.

I'll be back, enjoyed your blog for the first time today. Being from MI and OH originally, I remember those snowy days. I've left that all behind now and LOVE the desert!

Post a Comment